Means of production

Faced with growing demand from our customers and in order to remain competitive, Tmlaser invested in an automatic crimper HAEGER 824MSPe.

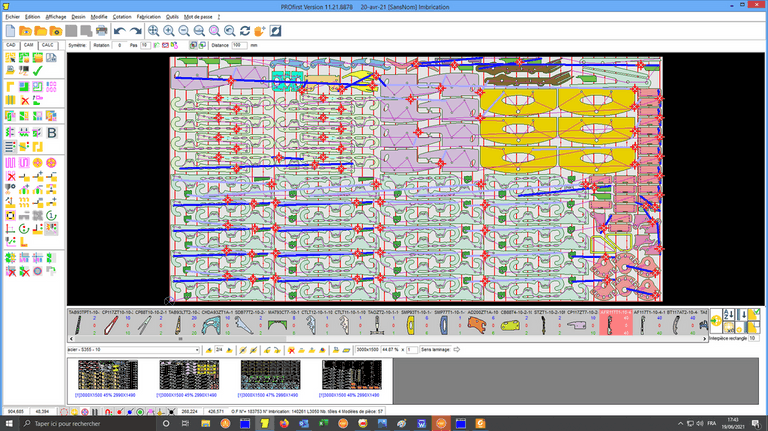

Laser cutting

Two machining centres table of laser cutting of 5000 W and 6000W

Field of action: 3000 x 1500

Thickness:

* ALU 0.8 to 15 mm

Automatic nozzle changer

Device for machining of tubes

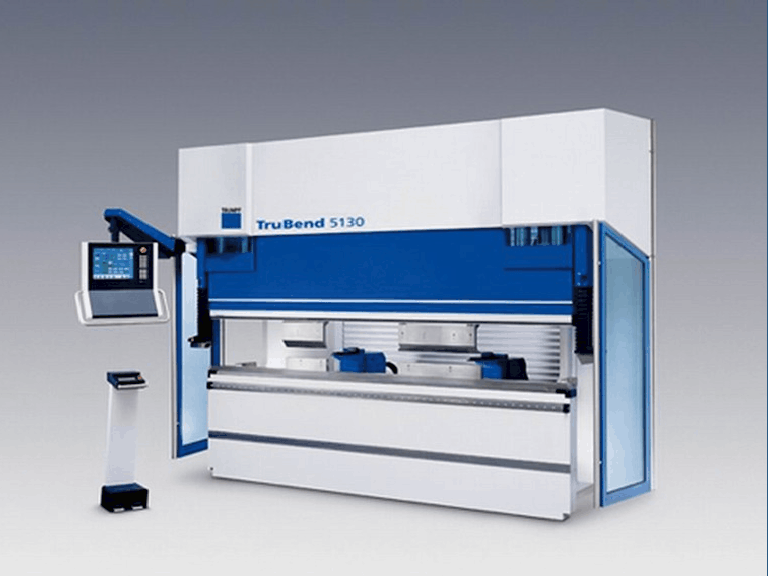

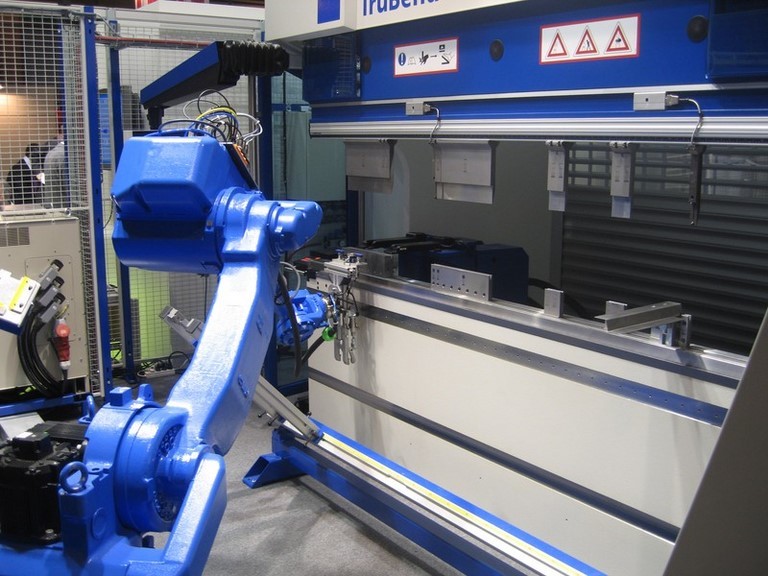

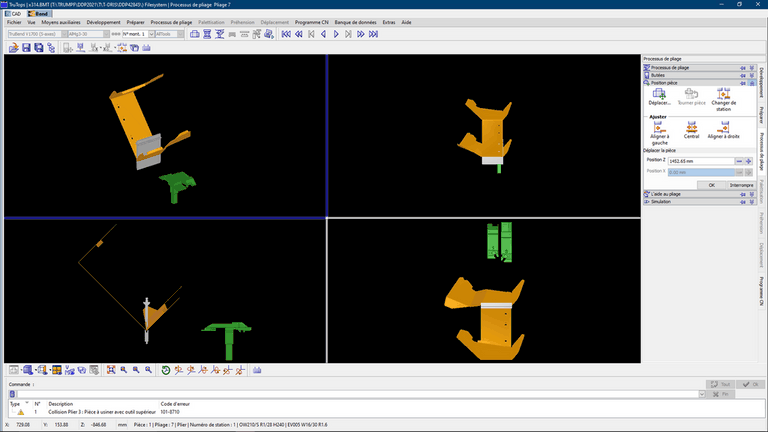

Bending read more...

We have a press brake 3 meters long, with a capacity of 170 tons with 5 axis digital and press, 130 tons 6-axis robot with a robot Motoman 7 axis can handling parts up to 50 kg payload . This one is used for high volume and repetitive production to guarantee quality and maximum productivity.

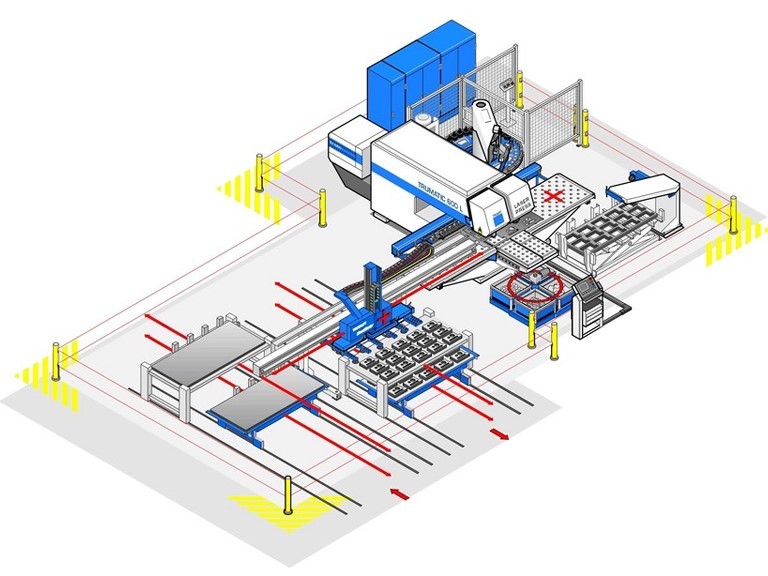

Combined Laser punching Read more...

TC600L 2200 W thickness of 0.6 to 8mm steel, stainless steel 6mm, 4mm aluminum.

We realize fully automated small and medium series.

We perform punching, deformation, milling ... And laser cutting complex contours before or after deformation.

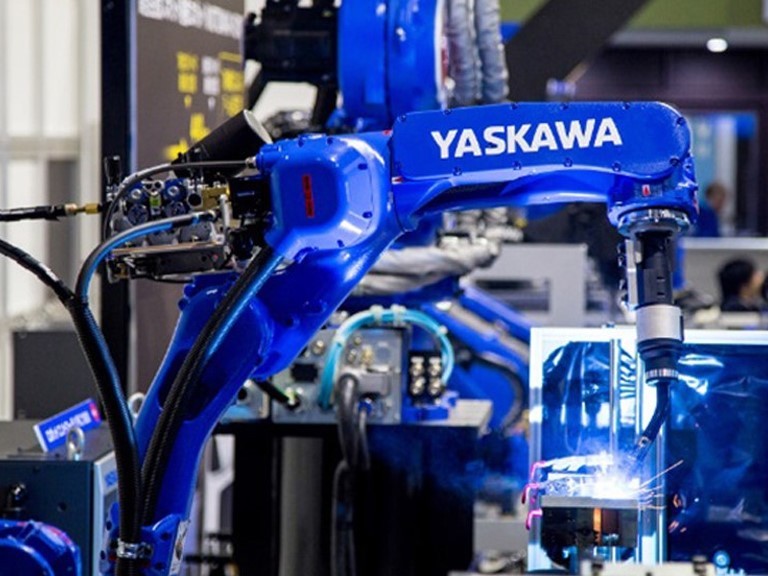

Welding

We weld on all metals steel, stainless steel alu. We have two posts KEMPI, a MIG - MAg pro 3200 and a MLS ACDC

as well as a welding UP6/XRC/RM2-250SE2 YASKAWA robot.

Crimping read more...

Optional 20,000 lbs. (90kN) modification available

Throat Depth 24” (610mm)

Stroke Length Adjustable 0 to 8.5” (0 to 220mm)

Speed up to 1400 insertions per hour

Repeatability +/- 2% of force setting

Footprint (LxWxH) 1499mm x 966mm x 2388mm (59” x 38” x 94”)

Fastener Range M2 to M10

Clinching Capability 1mm to 6mm combined thickness

Multi-Shuttle Tooling Platform for Nuts,Studs and Standoffs

AUTOMATIC BOTTOM FEED TOOLING (ABFT)

Automatique tools for studs M4 and nuts M4 alimenté par le haut.

Up supply tool for studs type FH M3 à M8 de longueur 6 to 30 mm.

Up supply tool for, pour Standoffs M3 à M5 de longueur 6 à 30 mm

Up and down supply tool for nuts type S M3 à M6

Up and down supply tool for, pour nuts type S M8

Finishing

We propose to our customers finishing operations such as drilling, tapping, countersinking, riveting and installing insert.

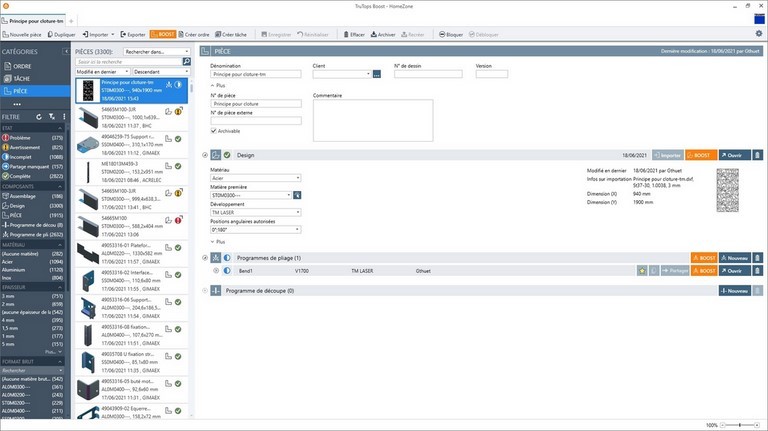

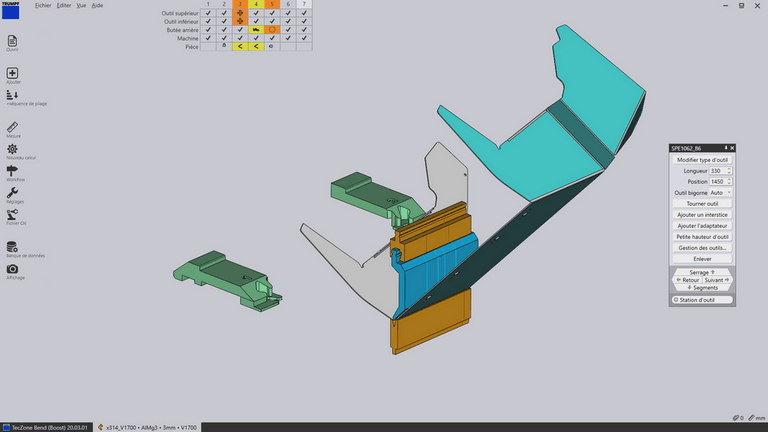

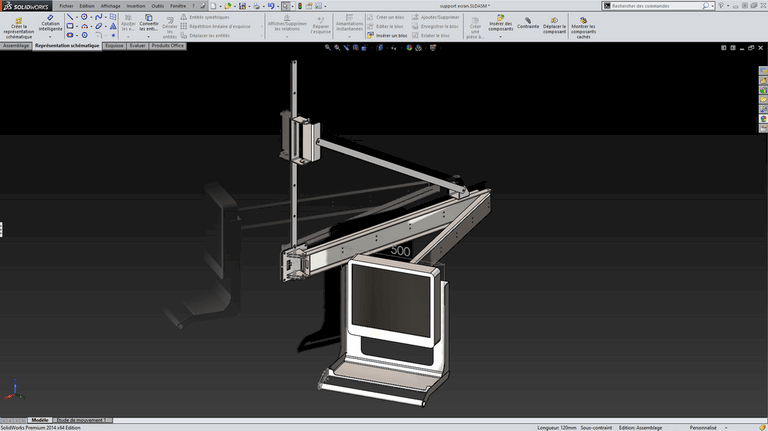

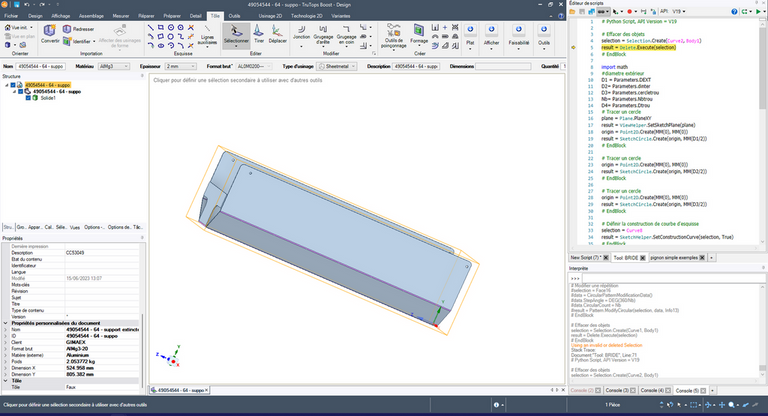

CAO FAO

We are equipped with different software from design to manufacturing.

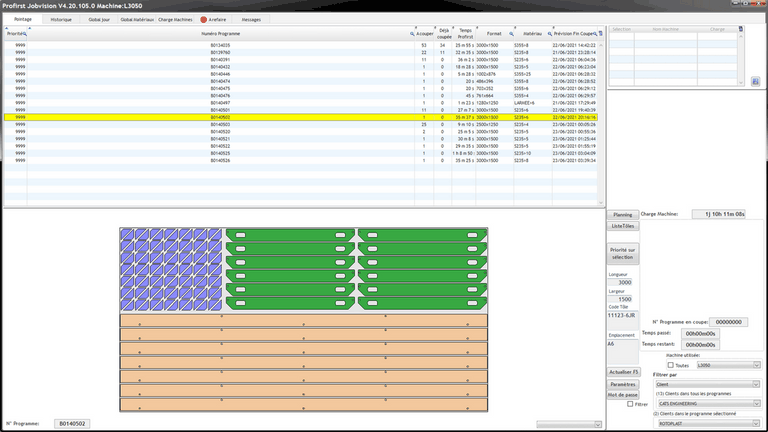

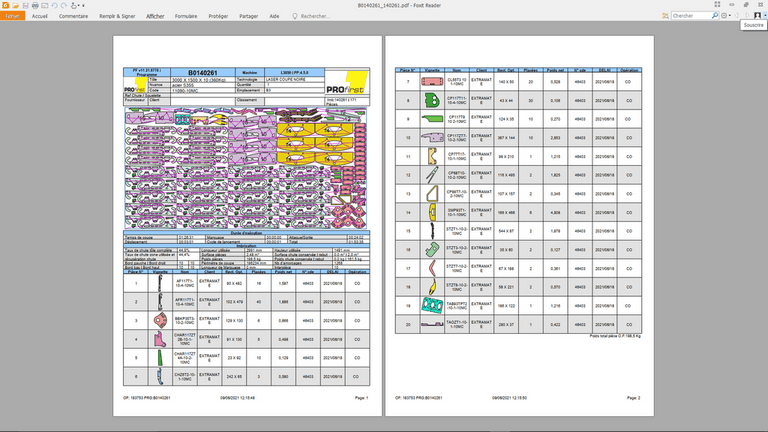

- TRUMPF FAO for LASER cutting, punching, bendind and pipe working.

- DEMLOG for nesting, production management and traceability of all our operations.

- SOLIDWORKS for the design and unfolding.

- ROMER et POWERINSPECT for 3D dimensional control.

We collect 2D and 3D files for achieving your sheet metal parts.

checking Tridimensional

We have the means of traditional control but also an arm Romer Sigma 2022 allowing us to check the parts in three dimensions.